Metal Casting

At PERIDOT, we specialize in providing custom metal castings services for customers in a wide range of industries. We offer several casting processes including green sand, investment, plaster, and die casting to produce ferrous and non-ferrous materials. PERIDOT will utilize the most effective method for each casting project.

Materials Available

- Aluminum

- Brass

- Bronze

- Ductile Iron

- Gray Iron

- Steel

- Zinc

- and MORE!

Current Metal Casting Methods

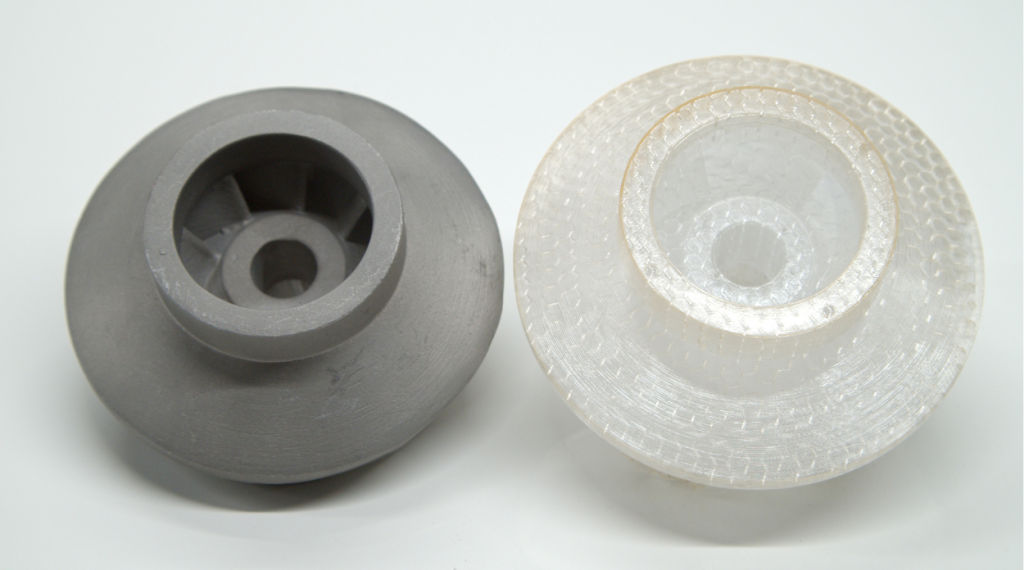

Investment Pattern Casting

3D printing with SLA technology provides an alternate method for producing investment casting patterns that are a lot more efficient and cost-effective. A foundry can produce a pattern that also services as a prototype for form and fit evaluation in a single day, providing a perfect match to the casting that would be produced if that exact pattern were to be used. An SLA part’s durability allows it to be put into an assembly for testing while preventing damage that often occurs in transportation and handling. Due to FDM being an additive process, patterns can be as complex or as simple as needed, without any impact on cost.

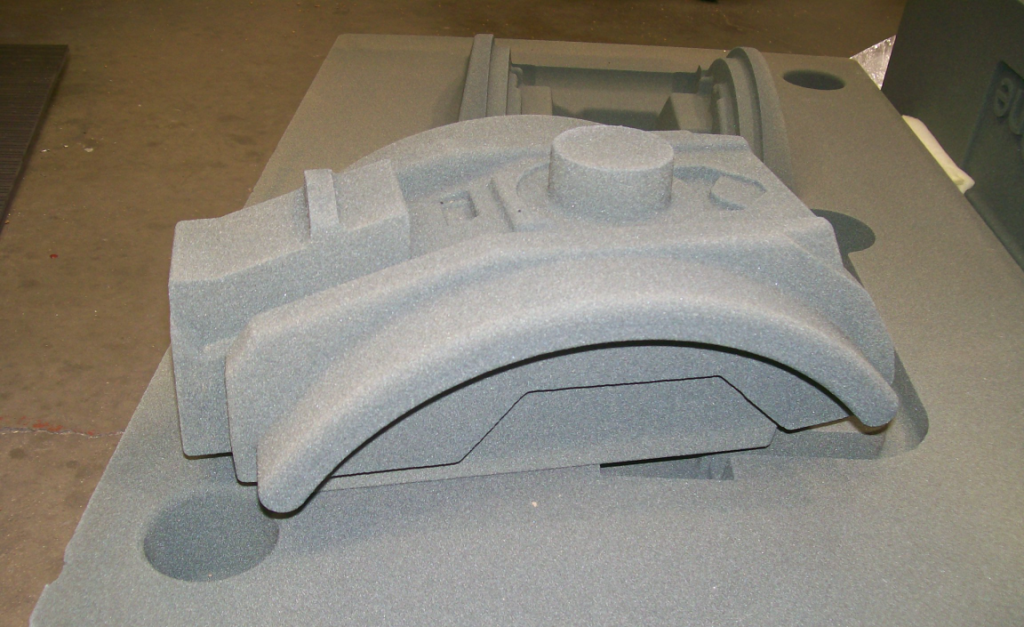

Green Sand Molds

Green Sand Castings are castings made using wet sand or “green sand” molds. The sand is not green in color not do the molds use “greensand”, a greenish color sandstone. Instead the same is called “green” because if has moisture in it before the sand dries out when molten metal is poured in the mold.

Optimize your low-volume production process with our cutting-edge tooling solutions, including precision tooling and 3D printed sand molds and cores, ensuring efficiency and cost-effectiveness for your manufacturing needs.

CNC Machined Patterns and Tooling

At Peridot, we specialize in providing custom metal casting services for customers in a wide range of industries. We offer several casting processes including green sand, investment, plaster, and die casting to produce ferrous and non-ferrous materials including: aluminum, zinc, steel, and iron alloys to name a few. We utilize the most effective method for each custom casting project. These methods include 3d printed patterns, sand molds, and cores along with CNC machined patterns and tooling.

Our engineering staff partners with customers to determine the best casting method for their product and application. Whether it is a prototype or high-volume production run, we have a method available to fit the job.